Cutting Edge Innovative Products

This Is A Movement

Superior Infection Control. Unmatched Durability. Unmatched Flexibility.

We are the most durable, hygienic modular stainless steel wall solution for high acuity spaces in hospitals. We provide a flexible system with a high speed solution for any hospital Operating Room, Clean Pharmacy, Central Processing Department, or ICU.

Healthier ENVIRONMENT

Superior Infection Control

Testing of the mfPHD Fortress™ System was completed by an independent 3rd party lab (Xenex Healthcare). The results demonstrated that the mfPHD Fortress System harbors 50% less bacteria than a traditionally constructed room.

Modular Design

UNMATCHED MODULAR SYSTEMS

The Fortress™ system allows wall sections/panels to be replaced after regular working hours. Traditional construction shuts the space down for several days, resulting in a decrease in service to patients and lost revenue.

Our replacement procedure also does not require standard ICRA containment. Panels can be cut on site, although outside the space, which eliminates the requirement for containment.

When a section of epoxy wall needs replaced, it can take 6 days (on average) to replace it. With our system it can be replaced in as few as 4 hours.

Modular EFFICIENCY

Wall Panel SYSTEMS

The Fortress™ wall panel system allows for rapid initial installation, which helps get your operating room up and running as quickly as possible. Repairing and replacing portions of the wall are simple, fast, and cost effective tasks. While repairing a standard epoxy wall can take days, the FORTRESS system can accomplish the same job in a period of about 4 hours, which eliminates costly downtime and delays in patient care.

Superior Quality

Casework

Extra storage for supplies and tools in an easily replaceable, clean environment. Keep your equipment in a convenient space with highly durable containment and easily cleaned surfaces.

Unmatched VERSATILity

Accessories

Our modular system also supports windows, sinks, and device support for plug-ins. Our modular panel system allows any panel to be easily removed, providing complete access to make necessary upgrades.

Smart Functionality

Doors

mfPHD’s Fortress™ flush-mounted door systems provide fully integrated solid core doors for increased infection control and durability. They are not only durable and easy to clean, but are built to fit active spaces. The doors come in both swing and slide styles.

Economically Superior

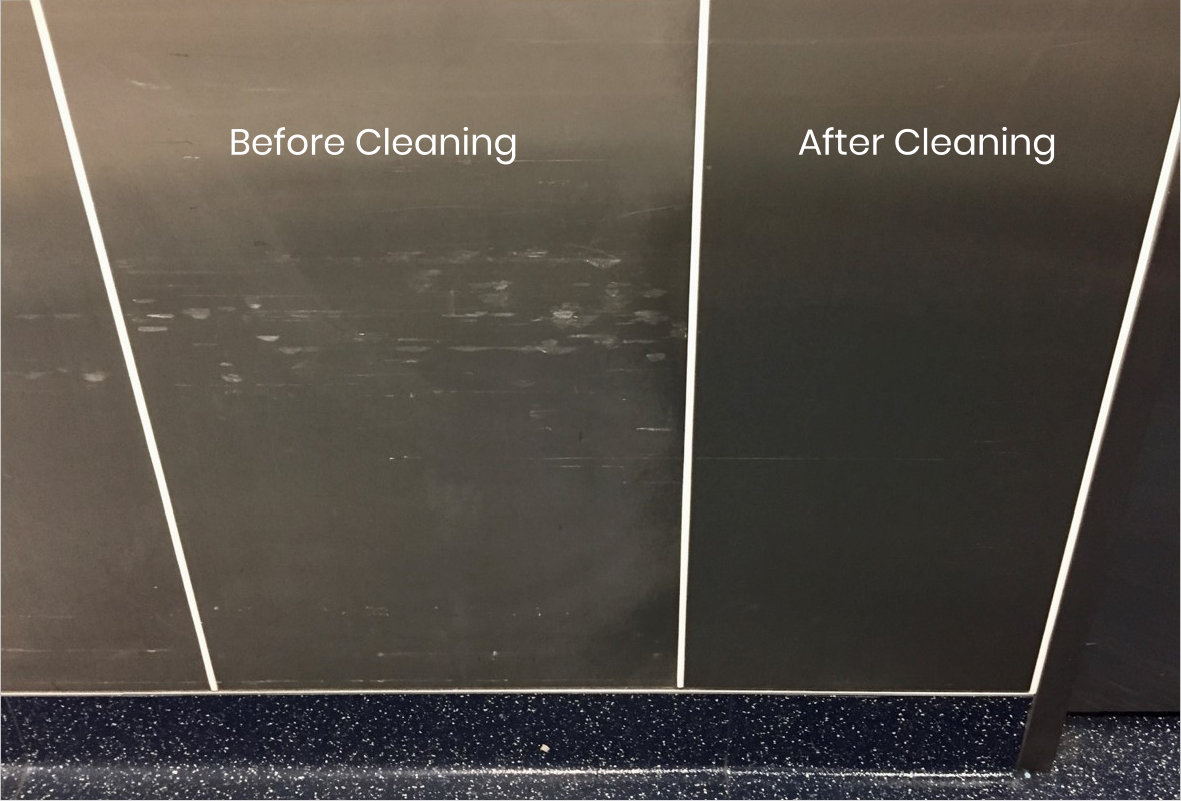

Unmatched Durability

Even after 3 years of use, and with a standard cleaning, The Fortress™ System’s stainless steel wall panels look brand new. The system has been tested and proven to be fire resistant for at least 60 minutes against temperatures of up to 1700 degrees.